Equipment and Softwares for NDT

Advanced Defect Detection using Non-Destructive techniques assisted by Machine Learning algorithms and oriented to Industry and Research.

Test Stations Assembly and Experiment Automation

Creation of Gigas for automated tests of electromechanical systems, circuits and sensors. Automation of experiments, interfacing to capture data in research equipment.

Software Creation

More than 10 years of experience in the development of software and hardware related to advanced signal processing for the characterization of materials and processes.

Portfolio

All these projects came from our hands.

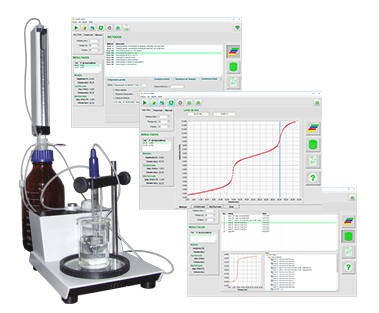

DiGital TITrator (With CIS SeNSOR)

Client: KEME Científica

Titrator Project with digital reading of titrant volume, by differential scanning with contact image sensor (CIS). LabXon Advanced Inspection was in charge of developing the hardware and software for this project with support from FAPESP.

control Software for NTD-RAM

Client: NDA

Control software based on the Advanced Resonant Spectroscopy technique for automatic detection of defects in the production line. Inspection of sintered metals, abrasives, brake pads, technical ceramics, porcelains, tiles and cast iron pieces.

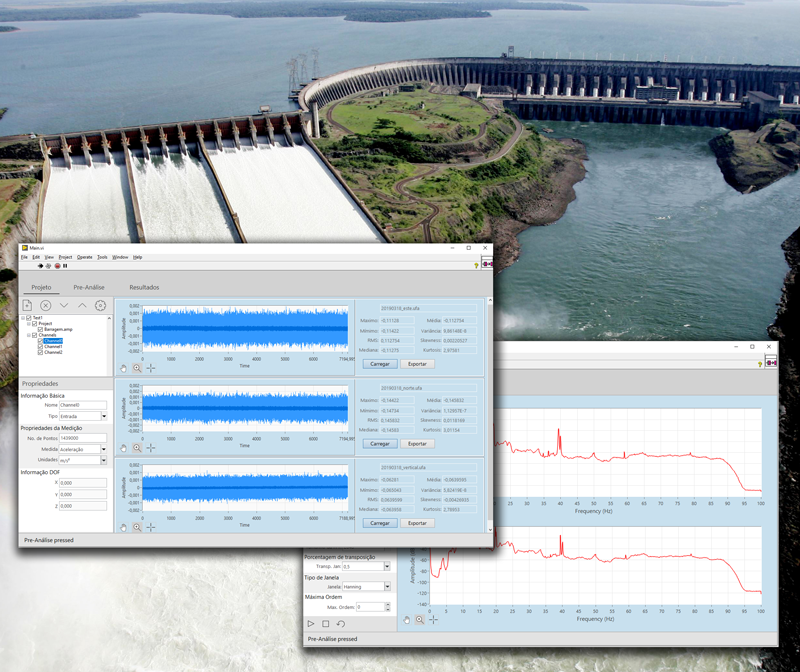

DYNAMIC MONITORING OF DAMS

Cliente: ITAIPU Binacional – CEASB

Application for the analysis of dynamic properties from acceleration records. Modal analysis of large structures such as bridges, buildings and barges.

CHARACTERIZATION

The first step in achieving an efficient classification of parts on a production line is an exhaustive knowledge of the defects that they can present. We are sure that this knowledge is the key element for the success of the classification algorithms that will be applied a posteriori and, therefore, we have implemented in our facilities several advanced characterization techniques that allow us to detect any defect that could lead to a possible failure of the part. The results of our characterization are compared with the acceptable defect levels established by the customer to obtain a highly efficient and personalized final classification system.

Another advantage of the advanced characterization of the parts under study is that, in addition to the classification of the parts as good or defective, it allows to establish with precision the reason for the rejection of a part. Thus, the customer will also have valuable information that will allow him to refine the production process and avoid waste of materials and time.

Variations in density, hardness, porosity, presence of delamination, fractures, and micro-cracks are easily detectable through the application of characterization techniques by our highly qualified personnel.

TRAINING

The evolution of computers in terms of calculating power, speed and storage has allowed, in recent years, an incredible development in machine learning algorithms. The detection of multiple objects in real time in images of increasingly higher resolution, thanks to the advancement of neural networks, the processing and interpretation of speech through recursive networks and other advances in artificial intelligence, are increasingly reducing the distance between what is possible for man and machines.

However, the success of these technologies is not just based on the ability to calculate. The correct choice of algorithm and the preconditioning of the data that will be used to train them is an extremely important factor to obtain greater precision, to improve the processing time and optimize the use of hardware resources. Our work team, with over 10 years of experience in applying advanced digital signal processing techniques, has the appropriate knowledge and practice to carry out this task.

We will be happy to put our experience at your disposal!

Contact Us

We are here for you, 24/7, to help you and reply within the hour.

- +55 (16) 98847-7032

- wcont@labxon.com

ONOVOLAB Innovation Campus

Rua Aquidaban, 1. Centro.

São Carlos. São Paulo.

Brasil.

MON-SAT: 9:00 – 18:00

GET OUR LATEST OFFERS